News Center

—— NEWS CENTER ——

On September 30, 2025, the International Energy Agency (IEA) released its latest technical report titled "Status of PV Module Recycling in IEA PVPS Task 12 Countries 2025." This report systematically analyzes policy regulations, retirement forecasts, and industry conditions across IEA PVPS Task 12 member countries, while focusing on government-funded PV recycling R&D projects to provide a comprehensive overview of global progress in photovoltaic (PV) module recycling.

The China section of the report was co-authored by Fang Lyu, Secretary-General of PV Committee of China Green Supply Chain Alliance (China ECOPV Alliance) . Key industry players such as Huanghe Hydropower, RESOLAR, Jingko Solar, Changzhou Ruisai, and DAS SOLAR were featured as representative cases from China.

About IEA PVPS Task 12

The International Energy Agency (IEA), established in 1974, is an autonomous organization within the framework of the Organisation for Economic Co-operation and Development (OECD).

Under IEA's Photovoltaic Power Systems Programme (PVPS), multiple working groups operate, including Task 12 - PV Sustainability Activities, which aims to promote international collaboration and knowledge sharing in sustainable PV technology development, with emphasis on environmental and social factors.

Report Content

This report presents a two-part analysis of PV module recycling in IEA PVPS Task 12 member countries: Part 1 examines national policies, projected module retirement volumes, recycling enterprises, and industry outlook; Part 2 summarizes government-supported recycling technology R&D projects. With global PV installations surging, establishing robust recycling systems has become critical as the wave of module decommissioning approaches. The EU has implemented mandatory Extended Producer Responsibility (EPR) through its Waste Electrical and Electronic Equipment Directive, while China, Japan, South Korea, Australia, and the U.S. are advancing related regulations and pilot programs. In 2022, EU nations collectively recycled 48,000 tons of PV module waste, with Germany leading in processing volumes. Professional recyclers primarily employ physical, thermal, and chemical processes, with current R&D focusing on improving recovery purity and efficiency for high-value materials like silicon and silver. The industry still faces challenges including high costs and immature markets, requiring coordinated policy, technological, and market efforts to build a circular economy framework.

Europe

In 2022, 18 European countries collectively processed 48,395 tons of decommissioned PV modules.

Italy recorded the highest collection volume (21,493 tons), followed by Germany (16,430 tons). Other major contributors included France (3,582 tons), Spain (2,603 tons), Belgium (1,855 tons), and the Netherlands (1,035 tons).

Germany: The Reiling Group serves as the core processor for crystalline silicon modules, while First Solar operates Europe's sole commercial recycling facility for cadmium telluride thin-film modules.

France: Processed 7,143 tons of modules in 2024 with 86.81% material recovery rate, 5.07% energy recovery, and 8.12% treatment rate. Non-profit environmental organization Soren manages national waste collection through tenders, with three designated processors (Gallo France, ENVIE 2E Midi Pyrénées, and ENVIE 2E Aquitaine). Thin-film modules are sent to Germany for processing, while ROSI Solar handles outputs from ENVIE 2E Aquitaine.

Spain: Companies like Solar Recycling and ROSI Solar (scheduled for 2025 operation) have obtained processing licenses.

Belgium: Since July 1, 2023, PV CYCLE implemented new eco-contribution fee structures where hard-to-recycle modules incur higher fees than standard ones. For common aluminum-framed crystalline modules, eco-contributions decreased from €2 to €1.5 per panel.

Asia & Australia & USA

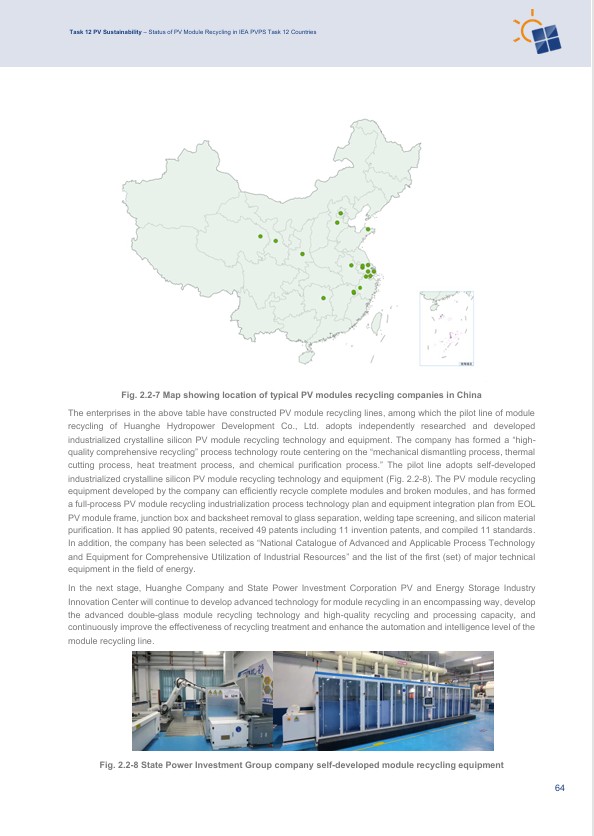

China: From 2023-2024, policy incentives and technological advancements drove continuous development in PV recycling. Industry leaders including Huanghe Hydropower , Jinko, Yingli, RESOLAR and Changzhou Ruisai have established recycling lines. Under conventional scenarios, cumulative waste is projected to reach 1 million tons by 2030 and 55 million tons by 2050; early retirement scenarios could increase these figures to 4 million and 66 million tons respectively.

Japan: The Ministry of Environment estimated 2,079 tons of PV waste collected in 2022 (1,638 tons recycled, 441 tons reused). Over 40 companies process PV waste, primarily using mechanical methods, with some employing thermal processes.

South Korea: Non-profit E-Cycle Governance, authorized by the Environment Ministry, operates a unified recycling system where member companies receive subsidies based on processing volumes. In 2023, 688 tons were recycled against total annual processing capacity of 14,700 tons.

Australia & USA

Australia: Total PV module waste reached approximately 40,000 tons in 2023, projected to exceed 100,000 tons by 2030. Companies like PV Industries and Elecsome have launched recycling operations.

USA: National Renewable Energy Laboratory models show 760 GW of crystalline silicon modules retired in 2022, exceeding 1 GW/year by 2030. Up to 43 companies across 27 states will provide recycling services, with SOLARCYCLE as a benchmark case.

China PV Recycling Plant Case Studies

Huanghe Hydropower adopts independently researched and developed industrialized crystalline silicon PV module recycling technology and equipment. The company has formed a “high quality comprehensive recycling” process technology route centering on the “mechanical dismantling process, thermal cutting process, heat treatment process, and chemical purification process.” The pilot line adopts self-developed industrialized crystalline silicon PV module recycling technology and equipment .

Changzhou Ruisai adopts special equipment for dismantling PV module peripheral parts by a mechanical method, stripping cover glass by a grinding method, dismantling PV laminates efficiently by a thermal method, and separating high-purity mixture, and so on. The company has a pilot line for dismantling EOL PV modules by a grinding method with an annual capacity of 3 000 tonnes, a pilot line for dismantling EOL PV modules by a pyrolysis synthesis method with an annual capacity of 20 000 tonnes, and a laboratory of dismantling PV modules by a chemical method.

RESOLAR Energy Technology (Shanghai) Co., Ltd. has independently developed the “GST (Green Swelling Technology) Green Separation Method”—a high-efficiency, environmentally friendly, low-cost, industrialized joint separation method—and can complete the production of 6N (99.9999%) grade silicon material. The recycled silicon material has significant advantages in terms of carbon emissions and cost and realizes the full cycle of silicon material and metal from EOL PV modules to new PV modules. The company has built and mass-produced a 10 000-tonne PV recycling line in Fengyang, Anhui Province , which produces recycled glass, aluminium, 6N-grade silicon, silver ingots, soldering tapes, and junction box cables with significant economic benefits. The company cooperated with Trina Solar to produce the world’s first fully recycled PV module in 2024.

DAS SOLAR is building a mechanical disassembly production line that integrates adaptive frame removal, thermal delamination, ultra-fine crushing, induced airflow, multi-stage component sorting, and comprehensive dust removal technologies. This technology enables the complete disassembly and reuse of photovoltaic glass and achieves high-efficiency separation of copper, silicon powder, and silver powder, reducing the energy required for purification.

About RESOLAR

Shanghai RESOLAR Energy Technology Co., Ltd. is committed to becoming a recycled material photovoltaic group with deep decarbonization. RESOLAR focuses on technological innovation and builds a world-leading solution for component recycling, impurity removal of damaged cells, recycled silicon materials and cells, and cascaded utilization of components. With professional technology and services, we help customers realize the recycling and reuse of waste photovoltaic resources, and make positive contributions to the development of environmental protection and new energy industries. For more detailed information, you can browse the official website: www.resolartech.com .

Latest developments/news

Contact information

Service Hotline: 13585742918 (Monday to Friday 9:00-18:00)

Enterprise email: ps@resolartech.com (Reply within 48 hours after receiving the email consultation!)

Company Address: Building 8, No. 1528, Wangxu East Road, Fengjing Town, Jinshan District, Shanghai (Caohejing Fengjing Park)